Production Facility

The number of hands employed to manufacture a zipper is as many as the resources required to be combined to produce it. A zipper can be produced with the cooperation of approximately 27 people. Both the heat and the coldness are used for the production process of a zipper which is manufactured from 5 different resources.

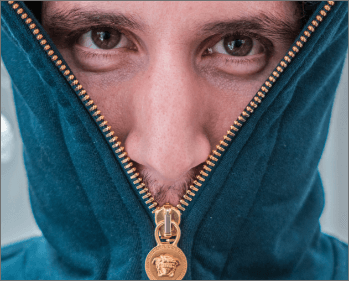

Alloys, wires, elements or lines, sliders and pullers are used for metal zippers. For Delrin zippers however, everything except for slider is made out of fabric or pom material produced from petrol. Nylon zippers are rarer compared to other zippers.

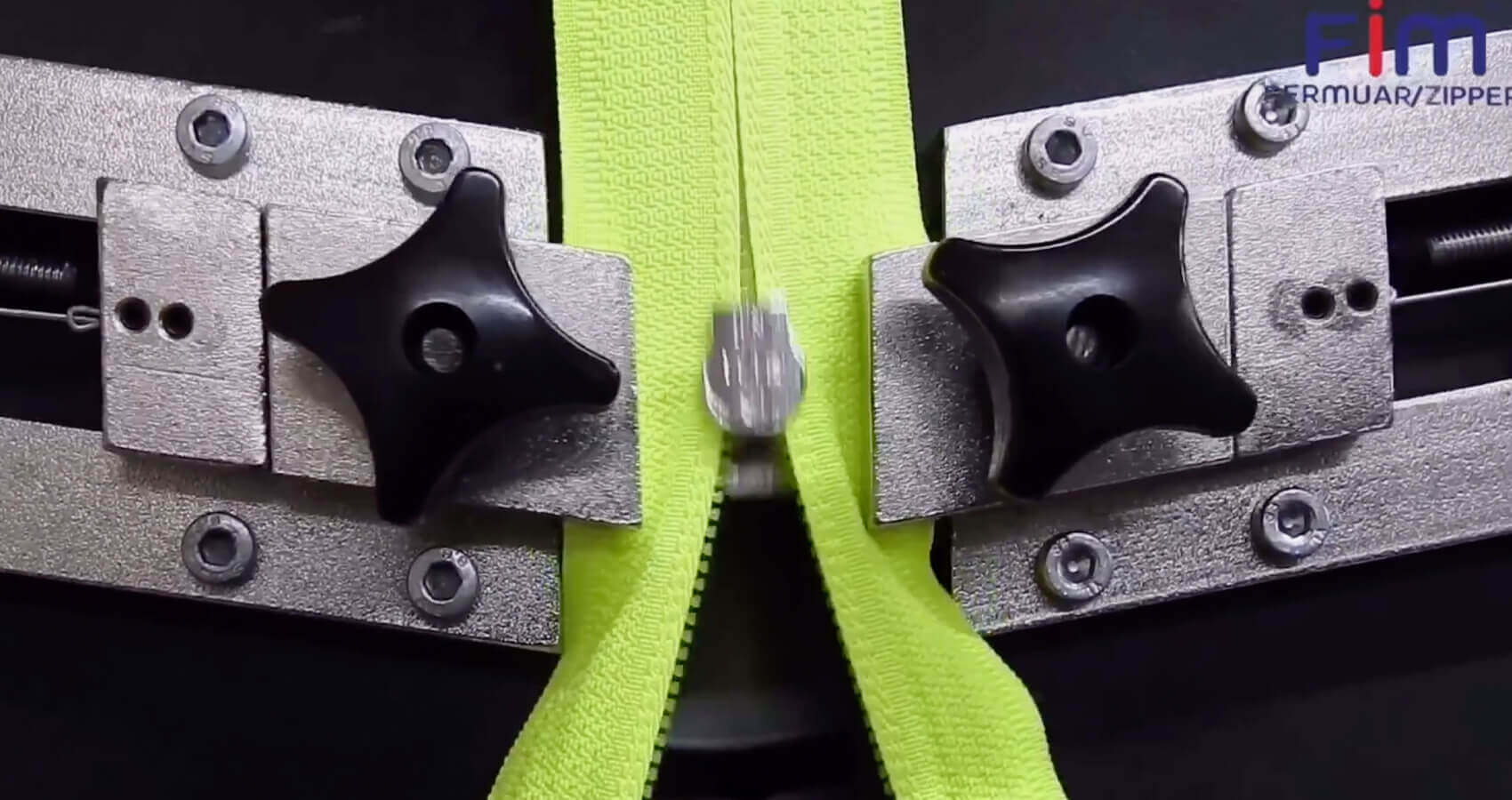

Upon receiving approval for the order, planning department calculates the required resource amount for the zipper and states it to weaving department and weaving department prepares the lines. It is followed by the painting process. If there is a special puller design, it is installed to the zippers.

Zippers which are subjected to necessary measurement and stopping processes after painting and coating, are transferred to the completion department. The product is then made ready by installing sliders and pullers as well as stopping and pin boxes.

Zippers which are approved for packaging after routine tests and analysis, are transferred to packaging department for packaging. After zippers are examined for their amounts and for their last analysis, they are transferred to logistics department for delivery and stock.